THE ORIGINS OF AET

50th Anniversary Archives

Part 2 – ‘The Early Years’ (1974-1990)

2024 marks AET’s 50th anniversary. Throughout the year, we are going to be exploring the archives and sharing stories of new and old. We will be reciting tales from the origins of the company back in 1974, to the turn of the century, and how AET is continuing to grow stronger in 2024. Join us as we delve into the history books in the second part of this chronicle.

In May of 1974, Anthony Taylor decided to write a new chapter in his career by establishing AET Engineering, a Yorkshire-based turbocharger engineering business. Starting out in his home workshop, Tony aimed to make AET the go-to company for all turbocharger needs in England.

With only a small team and limited resources, the beginnings were humble, but Tony was confident in its potential.

The garage beside Tony’s home provided adequate space to start AET, and his connections from his time at Mirrlees and Holset Engineering Co. proved invaluable in getting the name of AET off the ground.

Tony recalled,

“I had a good friend, Gerry, who could build a turbo. He used to come up at night.”

In the early days, Gerry Wood was a crucial part of the team. Tony spent his days traveling around the country, securing business, stripping down turbos, cleaning them, and sourcing the parts needed for repairs. Gerry would then arrive in the evenings to assemble the units.

Tony remembered,

“He’d be done with everything in about an hour!”

Of course, working out of a converted barn had its challenges. Tony’s wife, Glennys, who oversaw the daily operations of AET in the office space, remembered:

“The workshop was in the barn. The office was in the barn. It was freezing!”

Turbocharger engineering was a fledgling field in the 1970s, especially in motorsport, and Tony hoped to break into the racing industry soon. Despite the limitations of a home workshop, AET’s reputation grew quickly.

By 1976, demand had increased to the point that Tony decided to expand into a larger, dedicated facility in Horbury. Formerly a railway shed and Dunlop tennis ball storage building, the new location offered ample space for operations. Moving into this facility, however, was no small task. Tennis balls were found in every nook, and much of the building was in disrepair. But even with its quirks, the site was a big step up from the garage workshop.

Tony humorously recalled,

“I would be painting the floor with red paint, just for it to be ruined by my son Andrew kicking a football all over it seconds later.”

The entire team helped prepare the building, including new members Tom, Brian and Vic. During the setup, Tom even fell through a decayed office floor, narrowly missing young Andrew, who was probably playing with his football below.

Tom Francis, AET’s storeman at the time, would often lend a hand with any task that came his way; he was always willing to pitch in, as were all members of the team.

This all-hands-on-deck approach was something Tony sought to instill in every employee from the beginning, emphasising that no task was ever beneath anyone. This outlook remains a cornerstone of AET’s culture today, fostering a team spirit where everyone contributes.

Also in 1976, AET achieved a major milestone by becoming the exclusive UK distributor for KKK Turbolader, one of the leading German turbocharger manufacturers of the time. Known for their advanced turbocharger designs, KKK — Kuhnle, Kopp & Kausch — had been in operation since 1899. Around this time, AET also became a UK agent for Eberspächer, another German automotive industry leader.

These partnerships drastically expanded AET’s customer base, as UK manufacturers could now contact AET directly for repairs instead of liaising with KKK in Germany. Tony had tried to secure the KKK agency while he was focused on Mandeen Engineering some years previous. KKK had shown interest, however, it was quickly noted that they were only intrigued by Tony’s knowledge and attempted to pry him away from Yorkshire to come and work at their facility in Wellingborough.

Recalling the meeting in Stuttgart with KKK’s senior leadership, Tony said,

“I wasn’t interested. I was loyal to what we had. Even though it didn’t work out, I wasn’t bothered; it was just one of those things.”

AET’s steady growth and expansion into new premises marked the start of what would become a longstanding presence in the UK’s turbocharger industry.

AET began to work with major names such as DAF, as their 11-litre engine used a KKK turbo, and Tony’s experience with DAF through his time at Holset meant he already knew many key contacts there. This familiarity opened doors to similar opportunities with other commercial players, including Mercedes UK and Volvo Penta. AET handled various unique projects for Volvo Penta and secured work with Renault, Deutz, Liebherr, and Iveco too.

For Mercedes, AET established a routine of weekly collections and deliveries, transporting stillages packed full of reconditioned turbos. Each week, the team would spend a full day packing – after a week of building – filling every box, labelling them, loading up the stillages, and driving them down for delivery.

In 1980, an opportunity arose to purchase a building in Normanton, Wakefield. Tony was opposed to paying rent and had his eye on a former shoe factory tucked away in an industrial estate. An offer was made and later accepted. 50 years later, we are still in the same place, but with some considerable upgrades from how the building looked in the 80s for sure.

Most of AET’s business at this time derived from commercial vehicle diesel engine applications such as DAF, Saviem, MAN, Deutz, Mercedes, Scania etc. But a focus on the racing scene was on Tony and the team’s minds.

Tony recalled,

“We slowly expanded. We moved onto some larger projects.”

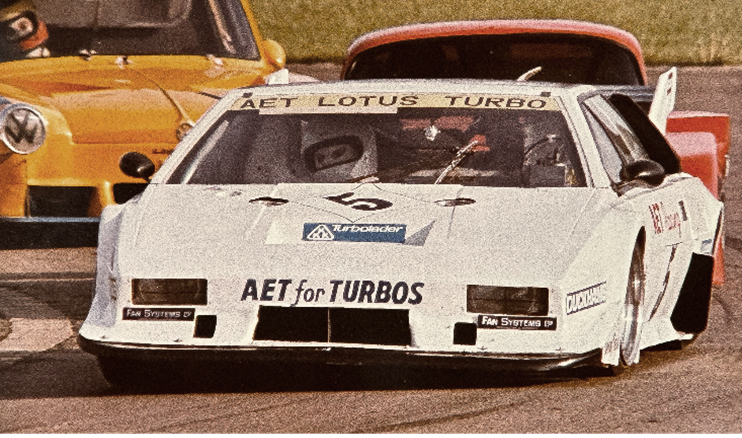

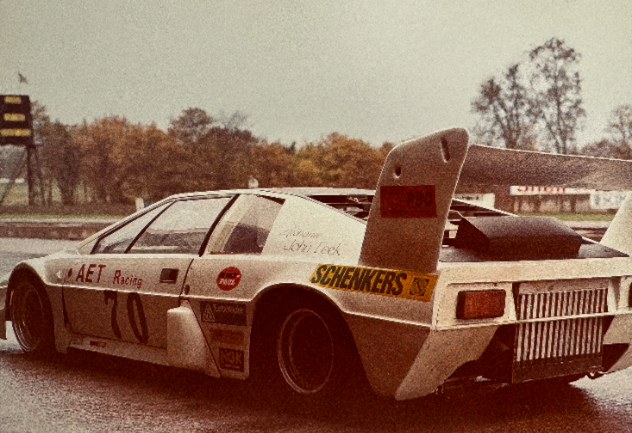

In 1980 once the team had settled into life in Normanton, AET (with the help of some close friends) built a group 5 race car.

Lotus Esprit

The car debuted in July 1980 at the Donington round of the German GP 5 Championship, competing against top teams like Zakspeed, Porsche, and BMW. It qualified second after the first practice and, despite a spark plug failure during the race, impressed enough to be showcased at the Jochen Rindt Show in Essen. This success encouraged further development of its 907-based turbocharged engine, eventually capable of 350-450 BHP, adjustable from the cockpit.

The team comprised of dedicated enthusiasts from various backgrounds, including farming, engineering, and business. John Leek oversaw the chassis and body design from his farm near Goole, while engine and turbo work was handled by Tony Tait and Tony Taylor at AET Engineering in Wakefield. In the cockpit was celebrated driver Tony Sugden, supported by his wife Rose on timing duties and their family handling the mechanics.

Built to 1980 Group 5 specs, the car featured a glued and riveted aluminium chassis, a fibreglass Lotus Esprit replica body, and advanced suspension with large, ventilated disc brakes to manage its 800kg weight and 165mph top speed. Its KKK turbocharged 1700cc Cosworth engine delivered impressive performance and a driver-controlled boost system.

The car won the BRSCC GT Championship and placed second in Class B of the Donington GT Championship.

In the 1980s, the slogan ‘AET FOR TURBOS‘ was introduced, marking the beginning of a lasting legacy for AET in the world of motorsport. The branding slogan (See image) was a simple but recognisable vinyl addition to the race cars, and it was a hit at the time. Fast forward to 2024, and we’ve decided to revive this iconic design, once again embracing the powerful and historic connection between AET and motorsport.

A certain Martin Thornton joined AET in September of 1985 following his unfortunate redundancy during the horrific pit closures of the 80s, which saw over 200,000 people out of work. Martin, from the local town of Castleford, initially joined AET as a turbo builder, and almost 40 years later, he is still here and is held in the highest regard by both his colleagues and friends. No task is too challenging, and no act of kindness is ever too much for him. While the term ‘legend’ is often used, it truly applies to Martin. Now in his 60s, Martin has accumulated a vast wealth of knowledge throughout his long tenure at AET and he is still an invaluable member of the team. To say he is appreciated would be an understatement.

The business landscape had begun to change as the 1990s approached. AET had focused mostly on the OE (original equipment) sector up until that time, serving just a handful of large customers.

Tony remarked,

“It was a simpler time, and our efforts were all about keeping those big clients happy. But then, things shifted.”

Yet, to withstand the dynamic market, Mr. Taylor and his team opened their services to a wider audience. Instead of solely dealing with 20 large clients, they were suddenly working with around 1,000 mid-sized ones as well.

Then, the internet came along and changed everything for AET. Suddenly, there were new opportunities for growth, and they had to figure out how to navigate this new digital world. The internet allowed businesses to connect in ways that weren’t possible before, and that meant AET had to adapt – diversifying their services once more to meet the needs of a wider range of customers.

Tony remembered,

“As the years went by, we kept evolving to keep up with the times. And of course, my son Andrew took over and helped the business grow even further.”

“There were some bumps along the way, of course – times when things didn’t go quite as planned – but here we are, 50 years later, still standing strong. It’s been a rollercoaster, but we’ve made it. And while we’ve changed a lot over the years, we’ve always stuck to our core values, which fills me with pride.” – Tony stated.