Turbo Reconditioning The Remanufacturing Process

The Parts

The Process

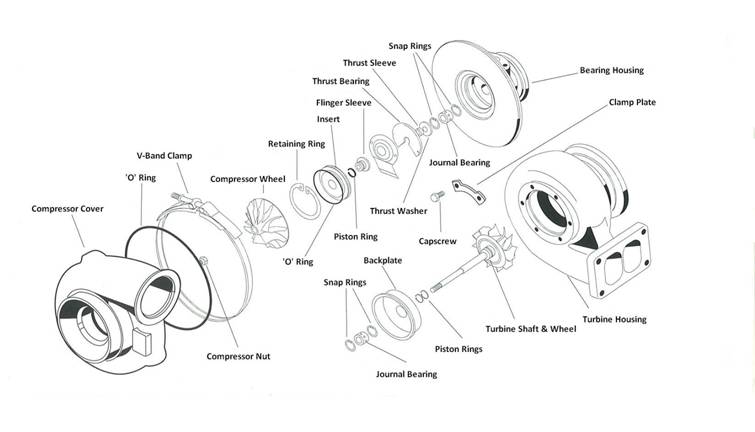

Every turbo brought in for remanufacture (sometimes referred to as turbo reconditioning) undergoes an initial inspection and is graded before being carefully dismantled for cleaning and degreasing. Journal bearings, seal rings, and other small items are discarded as a matter of policy.

Bearing and turbine housings are cleaned in a high temperature pressure wash tank and an ultrasonic cleaner to fully ensure removal of carbon deposits.

All major components, such as turbine shaft wheels, compressor wheels and housings, are checked against the manufacturer’s specifications; components that do not meet the required tolerance/high standards are replaced as a matter of course.

Components that need machining progress to our machine shop where milling, drilling, grinding and turning operations are carried out.

All items are then rigorously inspected to O.E. specification.

Once the rotating assembly has been put together, it is dynamically and VSR (vibration sorting rig) balanced to minute tolerances before being built into its compressor and turbine housings.

Our new centre housing rotating assembly (CHRA) balancing machine balances built CHRA assemblies to O.E. specifications.

The housings are aligned and the wastegate actuator (if fitted), which controls the boost pressure, is set and calibrated.

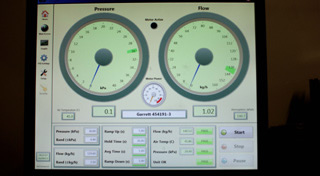

Our VNT-Min-Flow from G3Concepts is a high precision calibration tool developed specially for the turbocharger re-manufacturer industry.

It is designed to accurately measure the flow through the VGT mechanism and verify that it is set to the OEM factory setting, giving us the opportunity to adjust the critical minimum-flow stop to the correct setting before the turbocharger leaves our workshop.

This fully self-contained unit is capable of testing the minimum flow of any VGT turbocharger up to 190kg/h….

…including those with manifolds…

…with the aid of various custom designed adaptors.

Once set, you can be assured that your turbocharger will perform correctly when it is fitted to the vehicle.

See here for further specifications and manufacturer details for this great piece of equipment.

Upon final inspection, the unit is marked in compliance with our ISO 9001 quality procedures to indicate that it has successfully passed through our remanufacturing process. Once an identity plate, complete with unique, traceable serial number, has been attached to the housing the turbocharger is ready for use in accordance with our guidelines and fitting instructions.

Footnotes:

- [1] Original part, matching quality part

- [2] Core

- A core is a used original or matching quality part which will be remanufactured

- [3] Industrial processes

- An industrial process is an established process, which is fully documented.

- The size of the industrialized production batch is not limited; only one part could be remanufactured.

- In case of remanufacturing the minimum procedures used in the industrial process are: core management, core sorting, dismantling, cleaning of all internal and external components, replacement of all missing parts, restoration of all impaired, defective or substantially worn parts to a sound condition or replacement thereof, reworking, machining or performing such other operations as are necessary to put the part in original working condition or better, components assembly and final testing of each remanufactured part.

- [4] Specific technical specifications

- Specific technical specifications, established by the remanufacturer and consistently applied

- [5] Warranty as new part

- The remanufacturer must give a warranty for the remanufactured part which is the same as the warranty required by law for a “new part”, if one is required by law.

- [6] Clearly Identifies

- A non-removable, sustainable and uncoded marking is put on each remanufactured part

Or if you’d prefer you can use online chat or email us.