At AET, we’re serious about turbo tech, but we understand that not everyone is quite so passionate about turbocharger components!

Whilst there’s nothing wrong with not knowing your wastegate from your turbine, a little knowledge about components and what they do can be really helpful! Whether you’re looking to improve the performance or power of your engine, or just want to ensure you don’t have the wool pulled over your eyes by an unscrupulous mechanic when things go wrong, getting clued up is the way to go.

In this post, we’re looking at the intercooler, examining what it is, what it does and how it works, as well as providing some additional information about the different types of intercooler available.

What is an intercooler?

An intercooler is a mechanical device used to cool the intake air on engines fitted with a forced induction (either a turbocharger or a supercharger) system.

What does an intercooler do?

The intercooler’s job is to cool down the air after it has been compressed by the turbo or supercharger, but before it enters the engine.

How does an intercooler work?

Turbochargers work by compressing air, increasing its density before it reaches the cylinders of the engine. By squeezing more air into each cylinder, the engine is able to burn proportionally more fuel, creating more power with each explosion (see Turbocharging – a beginners FAQ for more details).

This compressing process generates a lot of heat, and increases the temperature of the air entering the engine. Unfortunately, as air gets hotter, it also becomes less dense, reducing the amount of oxygen available in each cylinder and impacting on performance!

The intercooler works to counteract this process, cooling the compressed air to provide the engine with more oxygen, and improving the combustion in each cylinder. In addition, by regulating the temperature of the air, it also increases the reliability of the engine, by ensuring the air to fuel ratio in each cylinder is maintained at a safe level.

Different types of intercooler

There are two main types of intercooler, which work in different ways:

Air-to-Air

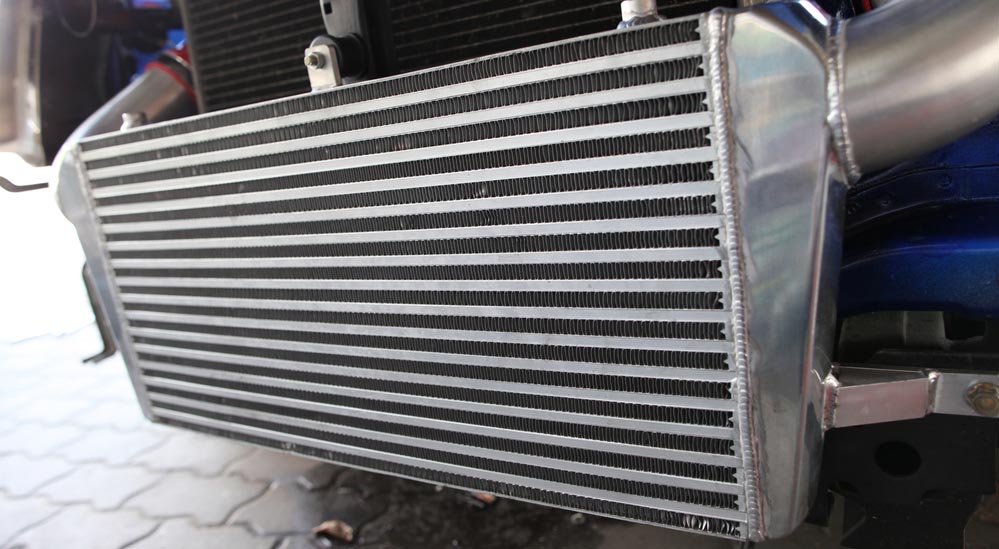

The first variant is the air-to-air intercooler, which works by passing the compressed air through a network of small tubes, past a series of cooling fins. The heat transfers from the hot compressed air into these cooling fins, which are in turn kept cool by the fast flow of air from outside the moving vehicle.

Once the cooled compressed air has passed through the intercooler, it is then fed to the intake manifold of the engine, and into the cylinders. The simplicity, light weight and low cost of air-to-air intercoolers makes them the most popular choice for the majority of turbocharged vehicles.

Air-to-water

As the name suggests, air-to-water intercoolers use water to lower the temperature of the compressed air. Cool water is pumped through the unit, extracting heat from the air as it passes through the unit. As this water heats up, it is then pumped through a radiator or cooling circuit, before re-entering the intercooler once cool.

Air-to-Water intercoolers tend to be smaller than air-to-air intercoolers, making them suitable for engines where space is at a premium, and because water conducts heat better than air, it is suitable for a more expansive range of temperatures.

However, the increased complexity, cost and weight associated with air-to-water intercoolers mean that they don’t tend to be found on vehicle engines.

Placement of intercoolers

Whilst in theory, air-to-air intercoolers can be located anywhere between the turbo and the engine, they are most effective where there is better airflow, and are usually placed at front of the vehicle, behind the grille.

In some vehicles, the engine layout prevents this, and the intercooler is placed on top of the engine – but airflow is typically less here, and the intercooler may be impacted by heat from the engine itself. In these cases, additional air ducts or scoops in the bonnet are usually added to improve airflow.

How AET can help?

At AET, our friendly teams are experts on everything turbo related, and if you’ve got a query, we’re always happy to help.

For assistance on any aspect of turbocharging, call us today on 01924 588 266, or email info@aet-turbos.co.uk.

1 thought on “Turbo tech 101 – what is an intercooler and how does it work?”

Comments are closed.